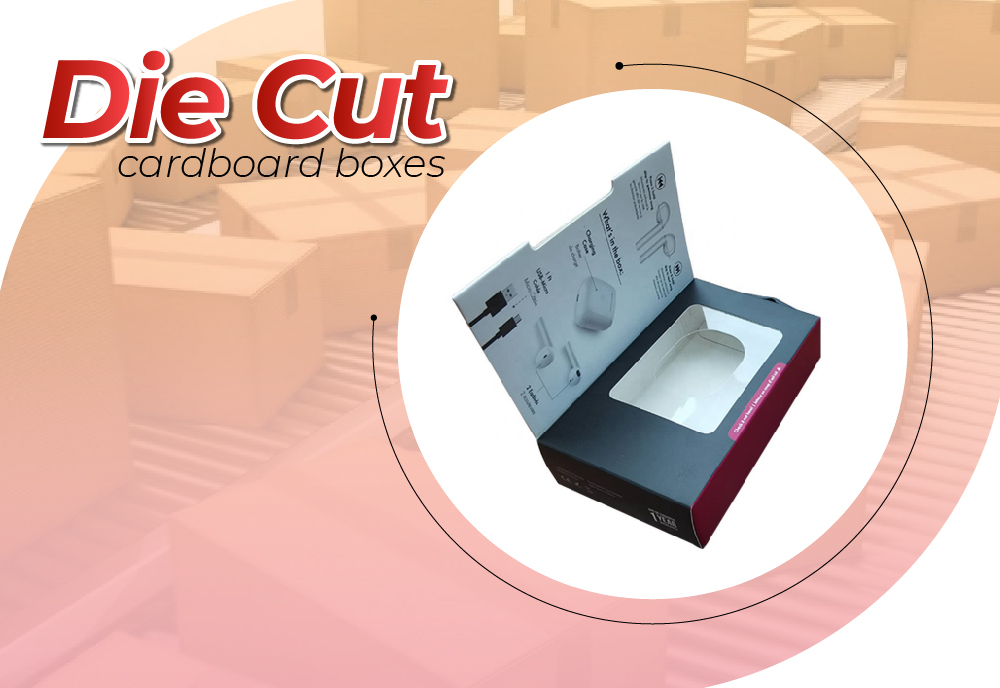

Before printing and finishing, every box is die-cut. This gives the box the ability to easily open and close. Custom die-cut boxes refer to boxes that are custom-made according to your specifications. It is not possible to make any cardboard box without a die cutter. Every product seller must have die-cut boxes to package their product beautifully. These boxes not only protect the product but also make the product look attractive and valuable to customers who are trying to choose the best product from the stock. aepnow

Personalization DIE-CUT BOXES

Every product manufacturer is increasingly embracing personalized die-cut boxes as a way to enhance the product’s appearance. It can also influence customers’ buying decisions, which is why custom printing is so important. The die-cut boxes look great when printed in vibrant colors and have shiny finishes.

Manufacturers have made custom-printed die-cut boxes an integral part of the marketing and sales strategies for their products. These boxes are the perfect example of a versatile design. You’ll be able to attract the most clients with a unique form and multiple windows.

This will increase your sales and help you get more customers. These boxes can be made more flexible by adding cutting edges. They are also useful to make products more attractive for clients.

Packaging

Packaging is essential for all products, small or large. Therefore, every product, from food to cosmetics to apparel, electronics, and clothing, can be packed in die-cut packaging boxes. The manufacturer can customize the box to fit their needs by making it according to size, shape, style, and material. Customers have the option of choosing from kraft, box-board, rigid, and kraft materials for making their boxes.

Customers can also choose the size, shape, and printing options for custom boxes. When it comes to gift preparation, the packaging is crucial. This is why cardboard boxes can be embellished with printing designs and other details that make the gift stand out. People often choose wrist watches, wallets, and perfumes to gift their loved ones. These products need to be presented in professional packaging. Many gift sellers use custom gift boxes. These boxes can be made using die-cutting and printed in vibrant colors that make the entire box stand out.

Necessary Precautions

Hygiene is a major concern for food items. Therefore, packaging must comply with the requirements of the authorities. Custom boxes are made from special cardboard and material that preserves the flavor of food items for a long period. Packaging must adhere to all standards, no matter if it’s retail food or prepared food.

Crusty foods such as cereals, cakes, and cupcakes are packed in custom-made food boxes, which are cut to customers’ specifications. You’ll have to take precautions when preparing these custom die-cut boxes. Take-out food boxes are also made of wax-coated cardboard material, which allows for direct contact with the food. These boxes provide unflawed waterproofing, lockup, and protection through the motor vehicle lock flap. The correct closure is provided by the correct tuck-end flaps at both the top and bottom. These boxes are safe and don’t require tape or other packaging materials. These boxes are often used in shops as display boxes. For additional protection, you’ll use different locks than flaps.

Manufacturing Material

Kraft material is a popular material for manufacturing custom boxes. Kraft material is used in packaging boxes for jewelry, cosmetics, and food industries. Kraft is lightweight and eco-friendly, making it easy to use and customize. Due to the increased demand for environmentally friendly packaging in the United States, kraft has been used in a variety of industries.

Kraft boxes are the best option for packaging herbal products due to their organic nature. The brown color makes the product look natural and organic, which is why kraft boxes are trusted by customers. Kraft material is perfect for die-cut boxes wholesale. Customers are prepared to pay more for products that are packed in brown boxes. These boxes also help reduce land waste, which is a major problem the world is currently facing. They are recyclable and therefore the preferred choice for companies who use boxes to ship products from one place to another.

Versatility

Forever, custom boxes will be the best choice for packaging. These custom-cut boxes offer versatile and fashionable solutions. They are available in a variety of sizes and shapes. Many of these boxes feature a window made from die-cut material that adjusts with the product size to ensure maximum visibility.

These boxes allow you to be as creative as you like. These custom die-cut boxes are very affordable and can be easily modified to meet the product’s requirements. These boxes are also eco-friendly and can be reused. These boxes will instantly grab consumers’ attention and influence their purchasing decisions. These boxes aren’t expensive, and you don’t have to spend a lot. These boxes provide additional protection and strength for the goods. These boxes reduce the risk of harm and increase shelf appeal.

Low-cost Packaging

Every decision you make when running a business must be based on the advantages and disadvantages. You want to make the best choices when packaging your products. Although there are many options for packaging products, the quality of these boxes has improved in recent years. This is due to the low cost of die-cut packaging.

It is simply that you would prefer one machine to produce the packaging. But it’s not only the main benefit that die-cut boxes provide. These boxes also provide uniformity, speed, as well as reduced packaging waste. Let’s take a closer look at some of the unique edges of die-cutting.

Advantages

These boxes will show that you care about the environment. This is not only a great idea for your business but also a smart move for the environment. These boxes require less packaging material, which ultimately results in less packaging waste. These boxes can be reused by customers in many different ways. These boxes can be used in many ways, including lights and planters. The ultimate solution to any packaging need is custom die-cut boxes. Professional companies can help you create a unique style and form for these boxes. These boxes are a great alternative to plain cardboard boxes that can be used for packaging. The packaging gives your product a unique look that increases its visual appeal. The boxes will have completely different die-cuts depending on the product.